Taylah joined our team recently to assume the role of chief mechanic for 'The Pedaler' and as team mechanic for Cobra9 Intebuild Racing. One year on from his move from Launceston, his skills as a mechanic and attention to detail are already widely known. Journalism student and Cobra9 Intebuild Racing team rider Tim Lofthouse sat down with Tay and got the back story on what brought him across Bass Straight.

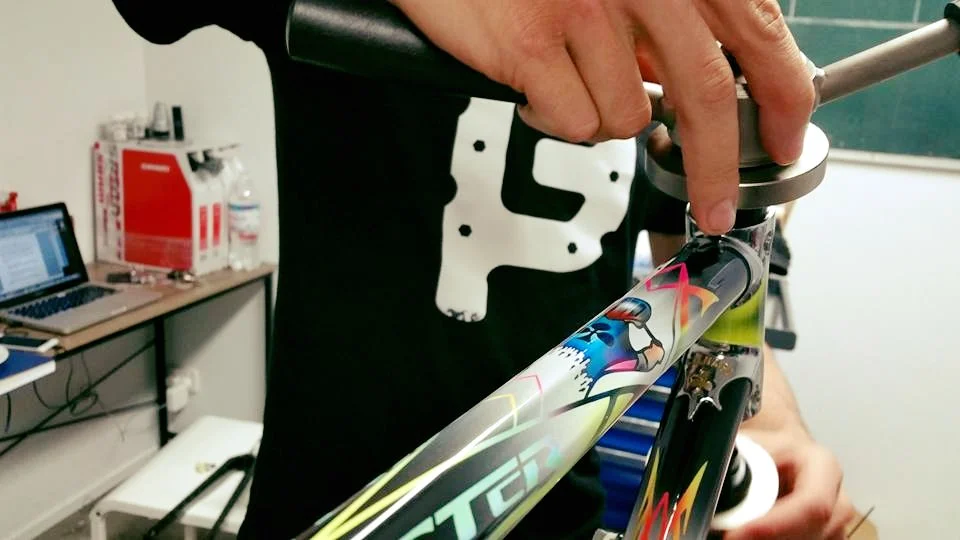

photo @cyclebro

Gaining Momentum

At 22 years of age, Taylah McLennan has devoted half his life to the colourful but cut-throat world that is professional road cycling. And he has no plans of changing course.

Surrounded by an abundance of rolling hills, winding countryside lanes, and a strong cycling community before most would consider giving their children training wheels, McLennan’s fascination with bikes began on the trails, away from the dangers of Launceston’s bustling and impatient traffic. Of course, he was unaware at the time, that he was laying the foundations for an enduring relationship with cycling, which he would later find out could take away life, as quickly as it could shape it.

Transitioning to the road, Taylah rode competitively through the junior ranks, but as he neared the sharp end of the sport, and after witnessing the death of a close friend whilst on a training camp in Tasmania’s Mersey Valley, he made the decision to pursue a career as a cycling mechanic.

“I was only 15 at the time, it was a huge reality check for me. It changed my perspective on the sport permanently. I didn’t touch the bike for 3 months.”

On the cusp of cycling’s elite, McLennan thoroughly understands how important the working condition of a bike is to its rider’s safety. Professional cyclists rely on six kilograms of carbon fibre between their legs to carry them across thousands of kilometres, often at speeds exceeding 100km per hour. Indeed, the preservation and function of that 6kg is a matter of life and death. After the incident in Tasmania, McLennan felt the onus was on him to ensure that no-one else close to him ever had to experience such a tragedy.

Although he had been working at a bike shop in Launceston for several years full-time before hand, it wasn’t until his first year riding in Under 23’s that he decided he wanted to turn the job into his profession. With the death of a close friend painfully present in his mind, and the remnants of a fire competitive cycling had left burning within him, McLennan was determined to be the best in his trade. Determined to make a difference.

His breakthrough opportunity came in the form of a travelling mechanic position with New Zealand professional team, Pure Black. After catching word of his talent, New Zealand bike manufacturer ‘Avanti’- which his store in Launceston sold – Tracked down McLennan for the position. “It was the first team I ever worked with…They needed a second mechanic for the Herald Sun Tour (Melbourne)… and because they were on Avanti’s’, someone put my name forward”.

After thriving in his role with the Pure Black Team, and with the excitement that came from working alongside professional athletes, McLennan set out in pursuit of other teams who could make use of his fast-developing skills.

Over the next six years, McLennan became an integral part of many highly-regarded cycling teams, and kept a countless number of riders safely on the road. His work has also taken him as far abroad as the Middle East, where he supported Australian team Search 2 Retain in the Tour of Iran. A typical day on tour for McLennan seems just as exhausting as riding the break-away all day – with a constant need to be attentive and focused on efficiency, no time for a lapse in concentration.

“We would start work before the stages at about 5:30am, and then usually finish up at about 9 in the evening,” “The stages in Iran were pretty hectic… rough roads, so there were a lot of punctures, broken wheels, crashes. A lot of very hard racing.” He recalled sitting in the team car with the race directors’ muffled Arabic voices shouting race updates through the race radio, “it was an experience, not knowing what anyone was saying” “he laughs.

Having just spent his first months away from teams in six years, McLennan is now living in Brisbane, working in Milton’s The Pedaler Cyclery. The shop also serves as a base for emerging NRS and Continental cycling team Cobra 9 Intebuild racing. This link was a big drawcard for McLennan, who is eager to be working with a team again after a year away from tours.

This will also add to his experience as he works towards his ultimate goal of working full-time on a European Pro Tour Team.

Former professional cyclist and manager at The Pedaler Cyclery, Josh Prete, has first-hand experience with McLennan’s ability, and says that his expertise working in the tours brings new strength to the workshop and their growing team as well. “His constant determination to learn and develop new skills is his biggest asset” Prete says. The two’s relationship highlights the unwavering level of respect pro and ex-pro riders like Prete have for their mechanics.

It’s difficult not to admire Taylah’s character and dedication. All too familiar with the difficulties which pursuing such a demanding and unpredictable career entail, the way that McLennan turned such devastation into life-long motivation, not only affirms his resilience, but proves he is a compassionate young man who takes immense pride in his work.

“If you don’t love what you do, you’re not going to stick around long, you’ve just gotta’ love it”.

Author: Tim Lofthouse